ESG's Test Results Show Greater Than 99% Efficiency

HOUSTON, TX / ACCESSWIRE / March 7, 2024 / Camber Energy, Inc. (NYSE American:CEI) ("Camber" or the "Company"), a growth-oriented diversified energy company, shared today the most recent announcement from ESG Clean Energy, LLC ("ESG") advising that the results of additional testing of ESG's water removal system for its patented carbon-capture technology indicate a water removal rate greater than 99%. This is a further improvement from the previously announced 90% efficiency rate following ESG's initial testing. All testing conducted so far exceed ESG's original modeled forecasts during the design phase which regarded an 80% efficiency a successful result.

James Doris, President and CEO of Camber, commented "It is great to see ESG achieve this significant testing milestone which represents an unparalleled result for the industry as a whole as it relates to being able to capture C02 cost effectively. This achievement will enhance our market position and expedite the next steps toward monetizing our license of ESG's expansive intellectual property portfolio."

What Does it Mean for the C02-Capture Industry?

Water molecules in an exhaust stream interfere with the carbon capture process, and ESG's patented system removes the majority of the water from the exhaust stream prior to the C02 being captured. Reaching the level of dryness supported by ESG's recent test results enables the better use of energy-efficient solid adsorber materials to capture the C02 instead of the high cost and energy intensive liquid adsorbers currently in use today. Put simply, ESG system is changing the industry by making it more cost-effective to capture CO2.

What Does it Mean for CEI

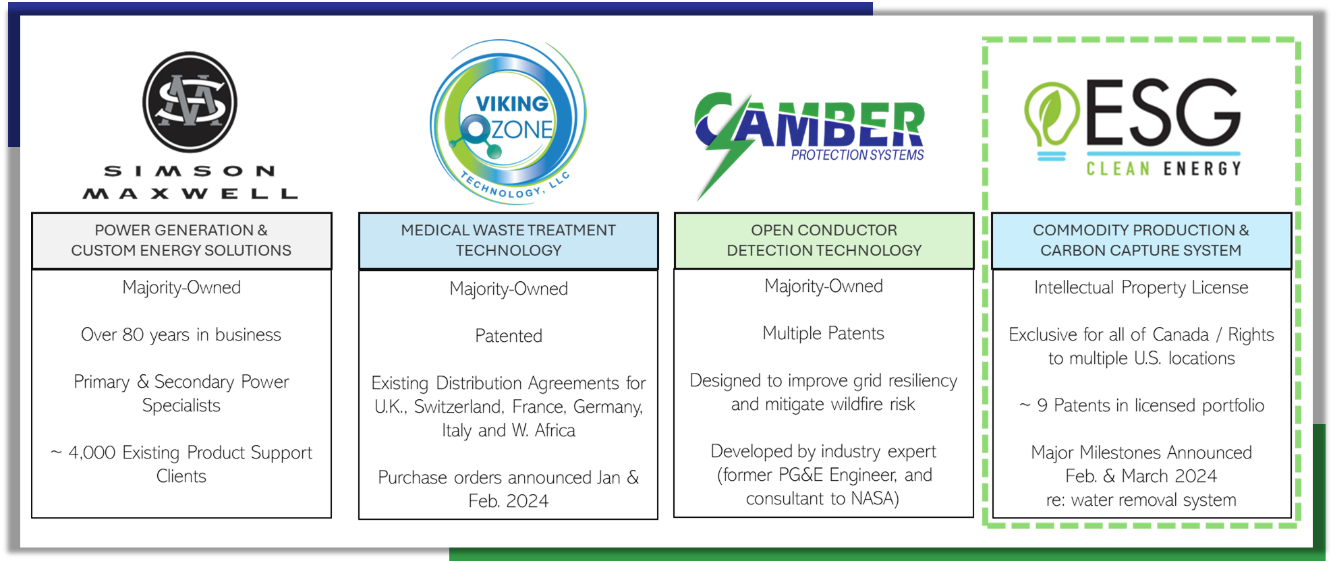

Camber, through a subsidiary, has licensed ESG's Clean Energy System, which includes an intellectual property portfolio of nine patents, for exclusive use in all of Canada, and for multiple locations in the U.S.

The market opportunity in Canada alone is significant. For example, as part of the Canadian government's carbon tax program, as of April 1, 2023 the federal carbon charge increased to $65 per ton of carbon dioxide equivalent ("CO2e"), and is set to increase annually each April through to 2030 when the carbon tax rate will be $170 per ton of CO2e. The escalating carbon tax is forcing industrial CO2 emitters to explore ways to reduce their carbon footprint.

The ESG Clean Energy System is designed to be a pragmatic, cost-effective solution to assist not only with reducing a user's tax burden by capturing CO2 cost-effectively but also to provide the user an opportunity to generate revenue from other features of the system. Camber intends to leverage existing relationships, including through its majority-owned subsidiary, Simson-Maxwell Ltd., to market the ESG Clean Energy System throughout Canada.

ESG's Recent Announcement

Regarding the additional test results of its patented water removal system, on March 4, 2024 ESG issued a press release which stated, in part:

****

ESG Clean Energy Reaches New Milestone of Over 99% Efficiency in Its Carbon Capture, Water Removal System

Achieving dry exhaust enhances and simplifies carbon capture

WEST SPRINGFIELD, Mass.--(ESG CLEAN ENERGY) / March 4, 2024 --ESG Clean Energy, LLC, developers of power generation/carbon capture systems with a nearly Zero Carbon output, announced today that results from continued testing of its patented water removal system exceeded a water removal rate of over 99 percent. Reaching this level of dryness from fossil fuel power generation emissions enables the better use of energy-efficient solid adsorber materials to capture carbon dioxide instead of the high cost and energy intensive liquid adsorbers currently in use today.

This major technical milestone was achieved by increasing both the systems' temperature and pressure differentials, enabling unprecedented exhaust dryness levels. This development makes it possible to conduct large- and small-scale direct carbon capture in a more viable and cost-effective manner. Testing was conducted at the company's 4.4MW gas-powered power generation plant in Holyoke that serves the local electrical grid.

"Reaching over 99% water removal is essentially making the emissions bone-dry," said Nick Scuderi, President of ESG Clean Energy, LLC. "With exhaust that dry, we believe capturing carbon dioxide can be done so much easier using low-cost and energy efficient solid adsorbers. This development provides a clearer path to applying this technology to all types of fossil fuel engines - from small and large power plants to the transportation industry."

ESG Clean Energy plans on implementing this technology across all its planned facilities and has licensed the technology to a subsidiary of Camber Energy (NYSE (Amex):CEI) for all of Canada and multiple locations in the United States.

How it Works

ESG Clean Energy's system treats the exhaust stream to remove the water vapor before it is treated for capturing CO2. This patented system consists of an advanced ceramic membrane that has been incorporated into a unique mechanical cooling system. With this technology, capturing carbon dioxide becomes both low cost and energy efficient. It is designed to be used on both large and small systems and can be retrofitted onto current operating power plants.

Capturing carbon dioxide (CO2) from fossil fuel emissions has historically been an expensive and energy intensive process. Fossil fuel emissions consist of a mixture of gases such as nitrogen, oxygen, carbon dioxide, nitrogen oxides, carbon monoxide, and water vapor. Separating and capturing the carbon dioxide in a gas mixture like this can be difficult. However, there are materials that have been developed that will selectively attach or react with the CO2 while letting the other gases pass by - except for the water vapor.

Water gets in the exhaust steam because it is a byproduct of combustion. When fossil fuel burns, it makes three things: heat, carbon dioxide, and water. The historical challenge has been water molecules interfering with the carbon capture process. Several scientific studies have shown how water negatively affects CO2 capture. For example, a study done by ETH Zurich Institute of Process Engineering and Stanford University stated, "In all carbon capture processes the feed steam contains water vapor, which interferes with the mechanisms involved in the adsorption of CO2."

[….]

****

About Camber Energy,Inc.

Camber Energy, Inc. is a growth-oriented diversified energy company. Through its wholly-owned subsidiary, Viking Energy Group, Inc., Camber: (i) provides custom energy & power solutions to commercial and industrial clients in North America; (ii) holds an exclusive license in Canada to a patented carbon-capture system; and (iii) has a majority interest in: (a) an entity with intellectual property rights to a fully developed, patented, ready-for-market proprietary Medical & Bio-Hazard Waste Treatment system using Ozone Technology; and (b) entities with the intellectual property rights to fully developed, patent pending, ready-for-market proprietary Electric Transmission and Distribution Open Conductor Detection Systems. For more information, please visit the company's website at www.camber.energy.

Forward-Looking Statements

This press release may contain forward-looking information within the meaning of Section 21E of the Securities Exchange Act of 1934, as amended, and Section 27A of the Securities Act of 1933, as amended. Any statements that are not historical facts contained in this press release are "forward-looking statements", which statements may be identified by words such as "expects," "plans," "projects," "will," "may," "anticipates," "believes," "should," "intends," "estimates," and other words of similar meaning. Such forward-looking statements are based on current expectations, involve known and unknown risks, a reliance on third parties for information, transactions that may be cancelled, and other factors that may cause our actual results, performance or achievements, or developments in our industry, to differ materially from the anticipated results, performance or achievements expressed or implied by such forward-looking statements. Factors that could cause actual results to differ materially from anticipated results include risks and uncertainties related to the fluctuation of global economic conditions or economic conditions with respect to the oil and gas industry, the COVID-19 pandemic, the performance of management, actions of government regulators, vendors, and suppliers, our cash flows and ability to obtain financing, competition, general economic conditions and other factors that are detailed in Camber's filings with the Securities and Exchange Commission. We intend that all forward-looking statements be subject to the Safe Harbor Provisions of the Private Securities Litigation Reform Act of 1995.

Camber cautions that the foregoing list of important factors is not complete, any forward-looking statement speaks only as of the date on which such statement is made, and Camber does not undertake to update any forward-looking statements that it may make, whether as a result of new information, future events or otherwise, except as required by applicable law. All subsequent written and oral forward-looking statements attributable to Camber or any person acting on its behalf are expressly qualified in their entirety by the cautionary statements referenced above.

Contact Information

Investors and Media:

Tel. 281.404.4387

SOURCE: Camber Energy, Inc.

View the original press release on accesswire.com